Gate Valve

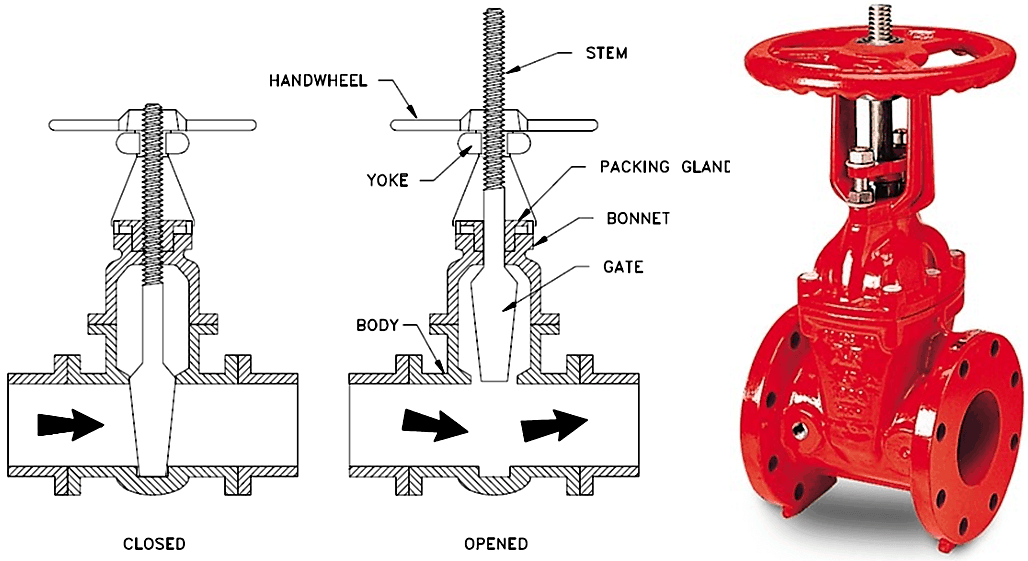

A gate valve is a control valve that allows or stops fluid flow. It offers a straight-through unobstructed passageway, resulting in minimal pressure loss over the valve. This type of valve also allows for a pig’s passage in cleaning pipe procedures. However, gate valves are slower than quarter-turn valves and should only be used in the fully open or closed position, not to regulate flow. Automated gate valves exist with electric or pneumatic actuators, but a manual gate valve is cost-effective since gate valves are typically used infrequently. Gate valves are also commonly referred to as sluice gate valves.

What is Gate Valve?

A gate valve can be defined as a type of valve that uses a gate or wedge-type disk, which moves perpendicular to flow to start or stop the fluid flow in piping. It is the most common type of that used in any process plant. It is a linear motion valve used to start or stop fluid flow. In service, the valve position is either fully open or fully closed gate. When the gate valve is open fully, the disk is completely removed from the flow. Therefore virtually has no obstruction to flow. Due to this, very little pressure drops across the valve when fluid passes through it. To achieve proper sealing, 360° surface contact is required between the gate and seats when the valve is fully closed. It should not be used for regulation or throttling of flow by a partially open gate because accurate control is not possible. The high velocity of the flow in the partially open gate valve may cause erosion of the disc and seating surfaces and also creates vibration and noise.

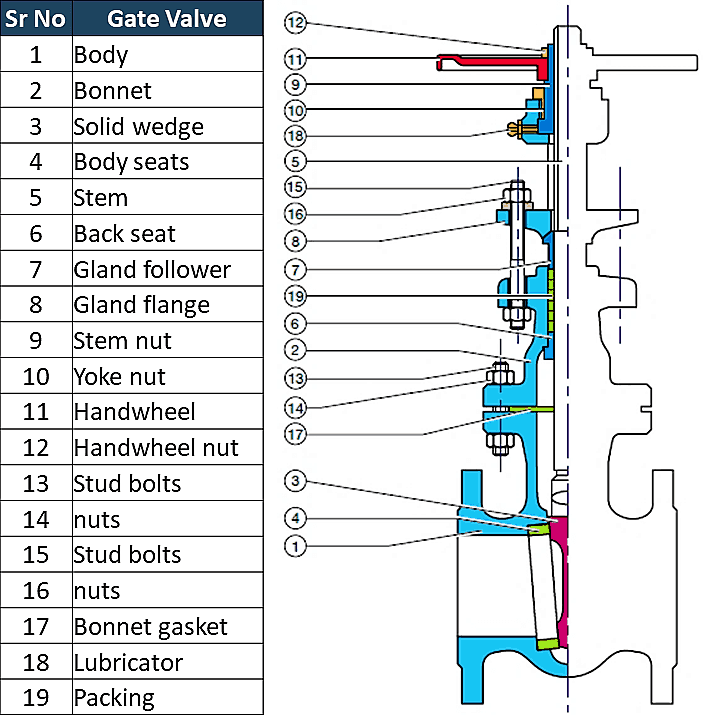

Here you can see the main parts of the typical gate valve. The disk of a gate valve is also known as a wedge. Gate valves consist of many parts as listed below

The gate valve is designed to provide good shutoff

The gate valve has no obstruction so the pressure in the valve doesn’t drop during operation and the loss is very minimal.

Most of the gate valves can be used as bi-directional

They are suitable for high pressure and temperature application and require less maintenance