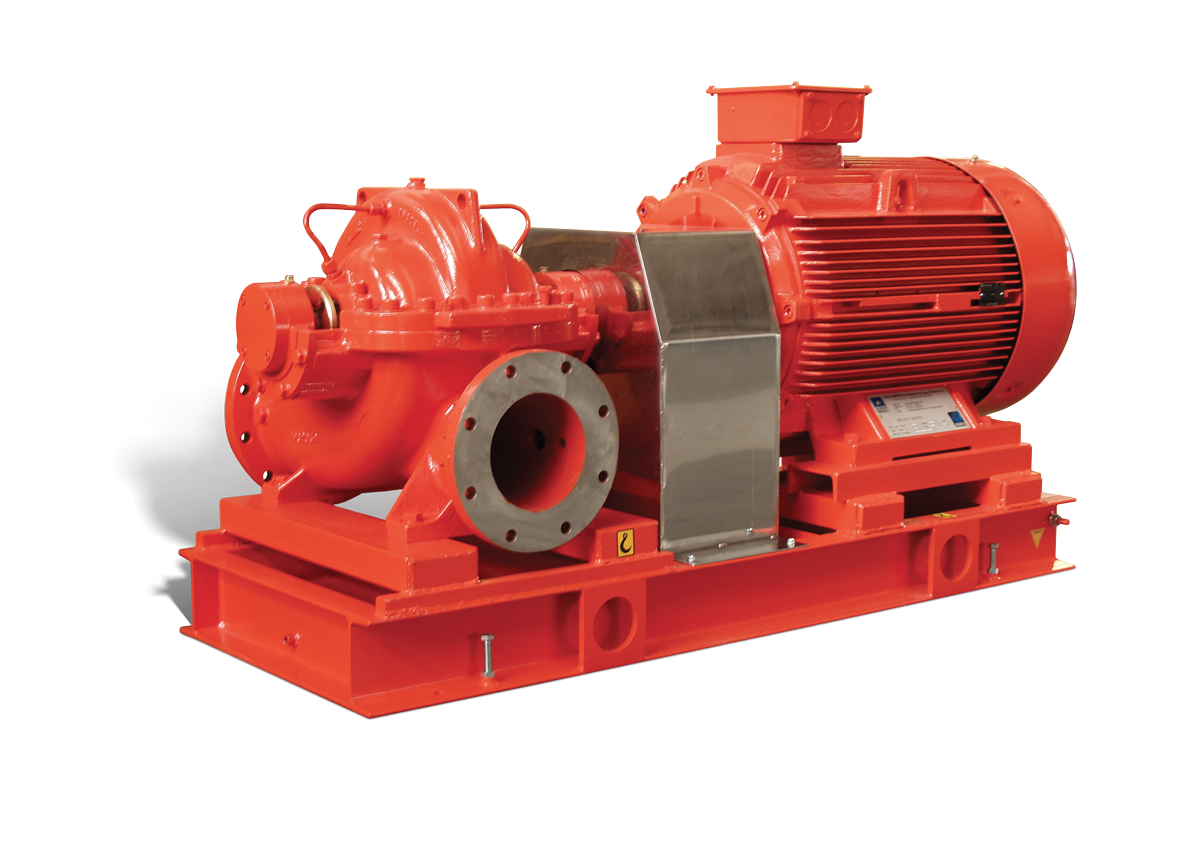

Fire Pump

Fire pumps serve an essential role in fire protection. These crucial fire and life safety devices ensure your fire protection systems have sufficient water pressure and flow rate to safeguard all building areas from potential fire and smoke damage. But not all fire pumps are created equal. Each type has its advantages and disadvantages, making it essential to understand your application requirements before selecting a pump design.

What is a Fire Pump?

Fire pump systems provide a high-pressure water supply for fire sprinklers, standpipes, and other water-based fire protection systems. These pumps ensure your building's fire protection systems have sufficient water pressure and flow to extinguish fires quickly and efficiently. The pump is powered by a motor and includes components like pressure switches, suction lines, and backflow preventers. Fire pumps are typically electric or diesel-driven, with electric motors providing minimal maintenance costs, while diesel models offer greater reliability in emergencies. Once activated, the fire pump draws water from a storage tank or other source and distributes it at high pressure to fire protection systems through a network of pipes, where it will then be dispensed onto the fire.

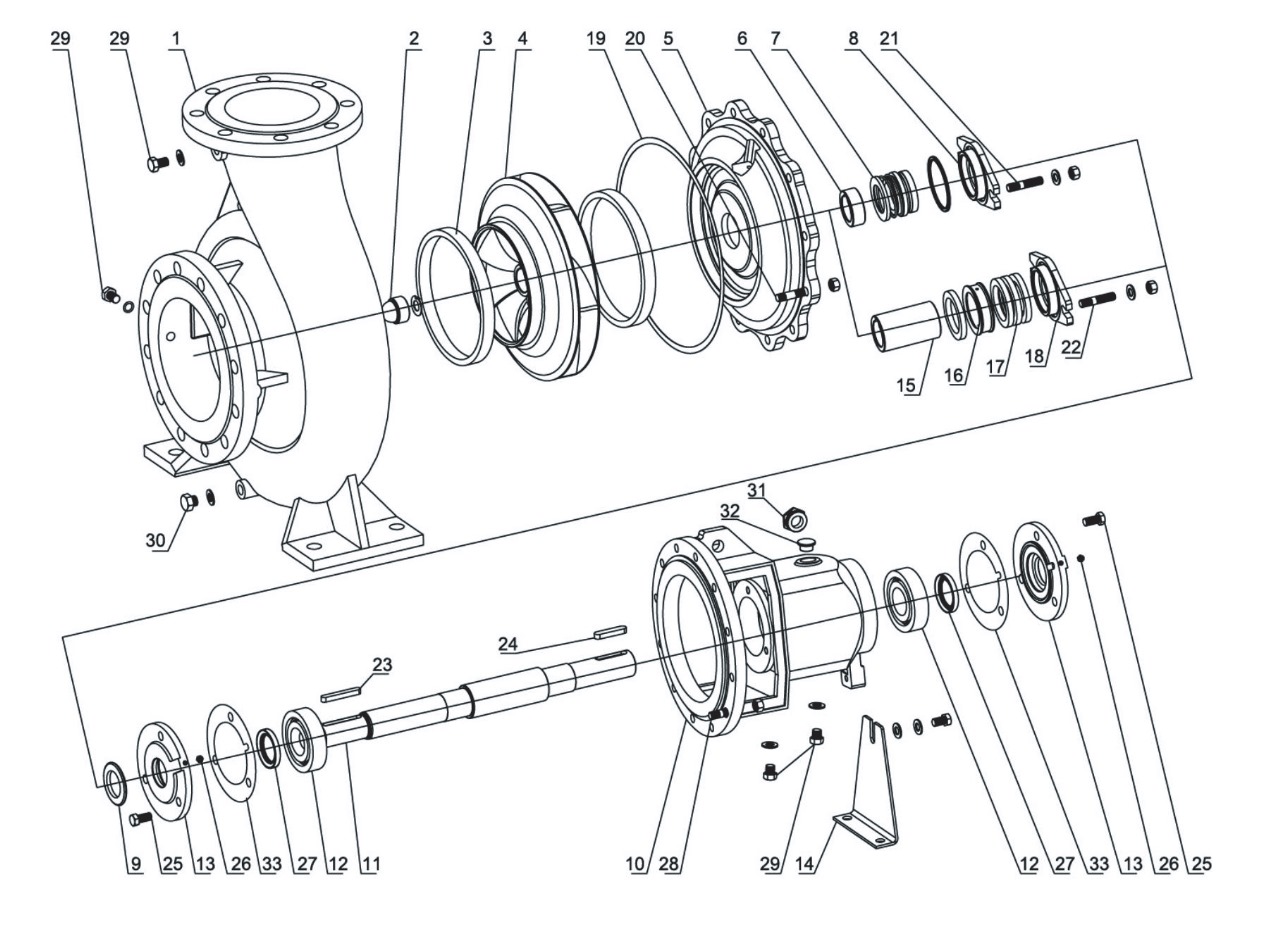

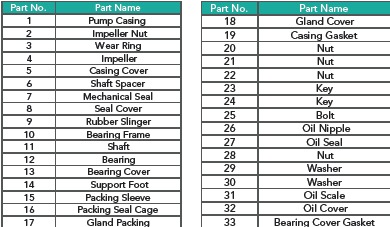

PA pumps are end suction back pull out centrifugal pumps which are designed complying to BSEN 733 / DIN 24255 standard. This series of pumps are built with the highest level of flexibility & modularity. They are ideal for handling water in various industrial & commercial applications. Bearing lubrication can be offered with oil as well as grease.

Designed for heavy duty applications

Extremely reliable

All service points like dipstick, lube oil filling, lube

oil filter, fuel pump, injectors are on one side

which is the cooler side. This adds to operator

comfort.

Lower operating cost

Easy maintenance – higher uptime

Superior design standards that minimize power

deration even at high ambient temperatures.